GE / IP FANUC Series 90/30 In Stock

How to Read a PLC Wiring Diagram

What is a Wiring Diagram?

A wiring diagram is a graphical representation of an electrical circuit. Often you’ll come across terms like an electrical diagram, electronic schematic, elementary diagram, or circuit diagram, all of which are synonyms of a wiring diagram. A pictorial wiring diagram makes use of simple images to show circuit components, while a schematic wiring diagram represents the circuit components and interconnections using standardized symbols.

All wiring diagrams include Power sources, Hardware components, Ground chassis, Connecting wires, Terminals, Letters, Numbers, and some Nomenclatures. However, unlike a layout or block diagram, a wiring diagram presents as closely as possible, the actual location and interconnections of all the components that make up a device circuitry. Simply put, a wiring diagram is a drawing meant to depict the physical design and arrangement of components and the connecting wires. Wiring diagrams are helpful when installing or troubleshooting electronic devices. They are widely used for the design, manufacturing, and maintenance of Programmable Logic Controllers (PLCs).

PLC Overview

Programmable Logic Controllers are rugged, special-purpose computers designed and built to operate reliably in extreme industrial environments. They were first developed to replace complicated electromechanical relay circuits in automobile industries- Landis Auto Ltd and General Motors. Today, PLCs are widely used in automating a variety of manufacturing processes and in industrial process control. For example, in an industrial setup, PLCs can be used to sequence automated devices like robots, control conveyor systems, collect data and communicate relevant information.

A PLC consists of a Central Processing Unit (CPU) with a Microprocessor and Memory, Input and Output (I/O) module, Power Supply, and a Programming Device. The CPU contains the Arithmetic and Logic Unit (ALU), which performs arithmetic functions and logic operations. The PLC memory within the processor stores the logic for program execution. There are two types of PLC memory namely: Random-Access Memory (RAM) and Read-Only Memory (ROM).

The PLC I/O module provides an interface to field devices. The input module connects the PLC processor to input field devices such as switches, start/stop pushbuttons, and sensors. While the output module provides an interface between the PLC processor and output load. Output modules enable the PLC processor to control field devices like electric heaters, motors, relays, solenoid valves, and pumps. The power supply powers the PLC components by converting 120/240V AC line voltage to 24V DC.

The programming device is connected to the PLC via a LAN cable, and it’s used to download a user-defined program into the PLC’s memory. It can also be used to edit and modify a PLC program. The most popular and commonly used PLC programming language is Ladder Diagram (LD), also known as Ladder Logic. As previously stated, PLCs were first developed to replace relay-based control systems. In hardwired relay control systems, electrical engineering drawings provided the blueprint for relay wiring layouts that resembled a ladder.

So, with the introduction of PLCs in most industrial setups, a PLC programming language that could mimic the layout of relay-based circuits was required. This was to make the transition easier for industrial engineers and technicians who had used relay control systems for a long time. That’s when Ladder Diagram was introduced as the first IEC 61131-3 standardized PLC programming language, designed to replace the physical wiring of relay-based control systems.

PLC Wiring Diagram

A basic electrical wiring diagram of a PLC control system consists of the following:

A) Power Supply Wiring

Whenever a PLC is connected to AC power supplies, the following letters represent:

- L: Live

- N: Neutral

- E: Earth, a symbol can also be used.

If the PLC is wired to DC power supplies, the following applies:

- Positive cable is connected to the ++ terminal

- Negative cable is connected to the –– terminal

- Connections to DC power supply should never be reversed.

B) Earthing

Usually, PLC earthing requires 2 wires of 2 mm each or larger. The PLC’s earth goes to the operational earthing circuit, as it cannot be connected to the same earth terminal as other power devices in the circuit. Also, sometimes you’ll find a PLC working without an earth connection. However, this is not advisable as the PLC may be subject to malfunctions caused by electrical interference.

C) Wiring of Inputs and Outputs

PLC input and output wiring lines are separated from each other to avoid signal interference. But when it’s not possible to separate the I/O signal wires, a shielded multi-core cable that is earthed at the PLC end is used. In addition, PLC I/O signal wires are kept at least 100 mm (millimeters) away from large-current and high-voltage wiring.

In designing PLC control systems, electrical wiring diagrams are converted to Ladder Logic wiring diagrams. This is especially necessary when you’re converting a machine to PLC control. As noted earlier, almost all PLCs used in industrial control applications are programmed using Ladder Diagram. And as the name suggests, Ladder Logic employs internal logic to replace all physical components in an electrical wiring diagram, except the ones actuated by electrical signals.

A Ladder Logic wiring diagram can be divided into two distinct parts. The first is the power portion which shows the flow of power to the PLC system. Bold lines are used to denote the power circuit. The second is the control circuit which is denoted by thin lines. If the power source is external to the PLC control panel, it’s usually not shown.

For example, in a PLC wiring diagram for motor control: the power circuit will show how power flows to the motor, while the control circuit will focus on how the motor is being controlled. In PLCs, the control portion of the wiring diagram uses standard Ladder Logic symbols. However, items such as fuses and disconnect devices can be found in both power and control circuits.

Ladder Logic PLC Wiring Diagram

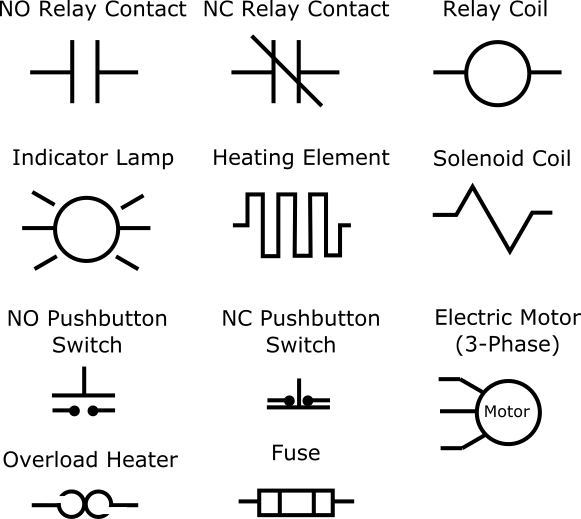

As the name suggests, the layout of a Ladder Diagram resembles a ladder in which two vertical rails are built among a series of horizontal rungs. The vertical rails represent the power connections as depicted on a relay-logic electrical schematic. Thus, using a Ladder Diagram you can write a PLC program with all the necessary input conditions, whether physical or logical, to influence output conditions. The code of instructions used includes a set of standardized symbols. The most common Ladder Logic symbols and their functions are as given below:

Characteristics of Ladder Logic Wiring Diagrams

A) The vertical lines in a Ladder Diagram indicate the power rails between which PLC circuits are connected. The Positive bar is on the far left while the Neutral or Negative power bar is on the right-end. Hence, current flows from the left-hand rail across the rung. The vertical power rails are normally protected from over-current conditions with a fuse or a circuit breaker.

B) The horizontal rungs show the relay contacts, switch contacts, relay coils, and the elements being controlled such as motors, lamps, solenoid coils…etc. They are drawn in between the vertical power rails.

C) The left side of a horizontal rung represents inputs that must be true to energize the connected outputs. So, each horizontal rung should start with input or inputs, and it should end with an output(s). The term input, in this case, refers to a control action like closing a contact switch acting as a PLC input. While the term output is used for devices that are connected to the PLC output, such as a motor.

D) The Ladder Diagram is read from left-to-right, then from top-to-bottom. After the top rung has been read from left-to-right, the second rung down is also read from left–to–right, then the third rung, and so on. This process is known as the PLC program scan.

E) Each horizontal rung on the ladder circuit defines a single operation in a PLC-controlled process. Thus, you should be able to logically visualize the control process through the horizontal rungs; as data flows from the inputs to the PLC components and unto the devices being controlled.

F) In Ladder circuits, physical electrical devices are depicted in their normal condition. For example, if a switch is normally open until a certain condition closes it, then it will be depicted as open on the ladder diagram. Similarly, a normally closed switch will be shown as closed.

G) Unlike conventional wiring diagrams where the interconnection between relay coils and relay contacts is represented with dashed lines, ladder diagrams associate relay coils and relay contacts by the label. It is also possible for a given electrical device to appear in more than one horizontal rung of a ladder diagram. For instance, you could have a relay contact that switches one or more electrical devices. In such a case, the same numbers and/or letters will be used to label that relay contact in each situation.

H) Another notable convention of ladder diagrams is that each and every wire in the relay circuit is labeled using a number that corresponds to common connection points. That is, when wires are connected together they’ll always have the same number: this common number designates a condition of electrical commonality for equipotential.

I) The inputs and outputs in a ladder diagram are identified using their addresses; the address notation used depends on the PLC manufacturer. This is usually the input or output address in the PLC memory.

Since Ladder Logic programming language is based on relay logic, the most common code of instructions used in PLC wiring diagrams are: Normally Open (NO), Normally Closed (NC) relay contacts, and other simple lines of code. The diagram below shows a typical PLC ladder-based wiring diagram:

Note: Despite the common norm that wiring diagrams should depict the actual locations of circuit components, Ladder Logic wiring diagrams do not show the actual physical locations of components in the circuit. Instead, the emphasis is on clearly showing how control is exercised. They have the capability to convey the complete sequence of operation of the PLC controller, unlike other conventional wiring diagrams.

How do you read a PLC Wiring Diagram?

For a better understanding of how you can easily read and interpret ladder wiring diagrams, we’ll look at simple electrical schematics which are then converted into PLC wiring diagrams (ladder diagrams).

Example 1: Circuit for Switching a Motor ON or OFF

The diagram below shows a simple wiring diagram of an electric motor. The electrical schematic in Figure 1a shows a d.c power source that is connected in series with a switch and the motor. In normal conditions, the switch used in this circuit is normally open and electrical power is supplied only when it’s closed; thereby switching the motor ON. When the switch is opened, the motor gets switched OFF.

Figure 1b is a single rung ladder diagram, in which the vertical rails L1 and L2 represent the d.c power supply. A Normally Open (NO) switch (acting as the PLC input) is connected to the electric motor (acting as the PLC output) across the horizontal rung. So by controlling the input, you can switch the motor ON or OFF.

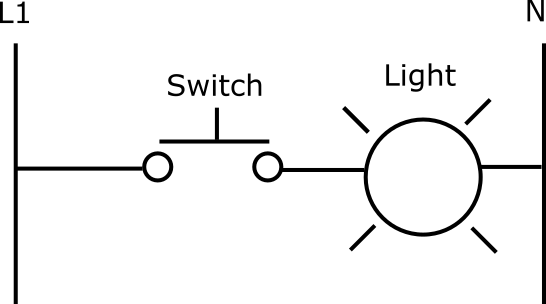

Example 2: Light Bulb Control Circuit

Let’s consider another basic electrical wiring diagram, in which an AC power source (L1-N) is connected in series to a NO pushbutton switch. The switch is then connected to a light bulb in series as well, and there is a neutral wire returning back to the AC power supply. So, when the pushbutton switch is closed, the electrical circuit is completed and current flows to the bulb making it light up.

You can then convert Figure 2a into a PLC wiring diagram by creating a simple ladder diagram as shown below:

In Figure 2b, L1 and N are the vertical power rails, with L1 representing Live wire and N showing the Neutral wire. The control circuit runs horizontally with the pushbutton switch and the light bulb across the rung.

Example 3: Motor Starter Control Circuit

The figure below shows an electrical wiring diagram of a three-phase Motor starter.

The above motor starter circuit has the following provisions:

- Pushbutton switch to start the motor: The motor is required to continue operating even after the pushbutton switch is released.

- Stop the pushbutton to halt the motor after it has started.

- Over-current protection (labeled as OL): This is necessary so that the motor can stop automatically in case of overload conditions. A thermal overload relay contact is used in this case.

- Limit switch: Used to prevent the motor from starting or stopping while running. However, in Figure 3a, the limit switch is not shown as it depends on an external interlock such as a pressure switch, flow switch, level switch, etc., depending on the application.

- Indicator lights: The circuit also includes indicators to show the ON or OFF status of the motor.

The above electrical physical layout of the motor starter circuit (Figure 3a) can be designed through Ladder Logic for PLC control, as shown below:

Interpretation of Figure 3b

Though not labeled, the vertical power rails indicate the power supply to the PLC system. You can also notice that the ladder wiring diagram (Figure 3b) has three horizontal rungs, which can be read as follows:

- Rung 1: Reading from left to right, we have: (i) NO (Normally Open) Start Pushbutton Switch labeled I1; (ii) NC (Normally Closed) Stop Pushbutton Switch (I2); (iii) NC Overload Relay Contact labeled I3I3; (iv) NO Limit Switch I4; (v) Relay Coil Q1 representing motor output. I1, I2, I3, I4, and Q1 are all connected in series. This means that the motor will run (expected output) if the start button I1 is pushed, stop button (I1) is not pressed, overload relay (I3) is not selected and limit switch (I1) is closed. Hence, the inputs in this PLC control circuit are: I1, I2, I3, and I4.

- In rung 1 still, we have a Normally Open (NO) relay contact labeled Q1 representing a motor input. This input is connected in parallel with the pushbutton I1 to allow for continuous motor rotation even when I1 is released. So if either I1 or Q1 is to be high, the motor will continue running if the other required conditions are also satisfied. Note: the condition of input Q1 depends upon motor output Q1. Such that, when the motor output Q1 is HIGH, the motor input Q1 will also be HIGH.

- Rung 2: This is read from left to right as well, and it consists of: (i) Normally Open relay contact representing motor input (Q1); (ii) Relay coil (Q2) representing motor indicator ON. The ON indicator (Q2) receives input from the NO (Normally Open) input (Q1) which is dependent on motor output Q1.

- Rung 3: Reading from left-to-right, we have: (i) Normally Closed relay contact representing motor input (Q1); (ii) Relay coil (Q3) representing motor indicator OFF. The OFF indicator (Q3) receives input from the NC (Normally Closed) input Q1 which depends on motor output Q2.

This entry was posted on February 22nd, 2022 and is filed under Uncategorized. Both comments and pings are currently closed.

PDF Supply sells used surplus products. PDF Supply is not an authorized distributor, affiliate, or representative for the brands we carry. Products sold by PDF Supply come with PDF Supply’s 1-year, 2-year, or 3-year warranty and do not come with the original manufacturer’s warranty. Designated trademarks, brand names and brands appearing herein are the property of their respective owners. This website is not sanctioned or approved by any manufacturer or tradename listed.

Rockwell Disclaimer: The product is used surplus. PDF Supply is not an authorized surplus dealer or affiliate for the Manufacturer of this product. The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because PDF Supply is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply. While many Allen-Bradley PLC products will have firmware already installed, PDF Supply makes no representation as to whether a PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. PDF Supply also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from Rockwell, its distributors, or any other source. PDF Supply also makes no representations as to your right to install any such firmware on the product. PDF Supply will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.