GE / IP FANUC Series 90/30 In Stock

Troubleshooting Tutorial: Common SLC 500 Faults – Part 2 : Processor Faults

Programmable Logic Controllers (PLC) such as Allen-Bradley’s SLC 500 Modular or Fixed style hardware are designed with capability of self-diagnostics. With Self-diagnostics, the controller is able to detect the operational status of every member module and report this externally through varying behavior of built-in LED indicators and internally via the diagnostic buffer. This is part 2 of our tutorial for troubleshooting common SLC 500 Faults.

In this section, we will discuss common SLC 500 Processor Faults.

Processor Faults

NVRAM Error

| Hardware Fault Type | Processor |

| Error Type | Powerup |

| Error Code | 0001 (HEX) |

| Error Description | NVRAM Error |

| Cause | Mostly due to noise, power surge, grounding, and loss of capacitor or battery backup power. |

| Resolution | a. Program Download and Run b. Automatic loading of program |

| Detailed Steps: | -To download program and Run, refer to the appendix at the end of this document. -To configure automatic program loading: Access the Custom Data monitor. Type in S:1/10 as seen in the image below and put 1 in the Value tab. This forces the S:1/10 to 1 and triggers automatic loading of program every time a power cycle is executed. |

Watchdog Timeout

| Hardware Fault Type | Processor |

| Error Type | Powerup / User Program Instructions |

| Error Code | 0002 (HEX) / 0022 (HEX) |

| Error Description | Unexpected hardware watchdog timeout; The user watchdog scan time has been exceeded. |

| Cause | Mostly due to noise, power surge, grounding, loss of capacitor or battery backup power, improper use of JMP, LBL and too complex nested routines and loops in the user program. |

| Resolution | (a) Program Download and Run (b) Automatic loading of program (c) Re-structuring and simplify program; eliminate excessive use of JUMP, LBL, and looping instructions. (d) Adjust watchdog time duration |

| Detailed Steps | (a) To download program and Run, refer to the appendix (b) see detailed steps of NVRAM Error, to configure automatic program loading. To adjust watchdog time duration; 1. To adjust the watchdog time, open the Data File S2. Locate the tab SCAN TIMES. The default value is 10 (100 ms), but it can be increased up to 250 (2.5 seconds). Caution should be observed when doing this. Typically, the default Watchdog time is the optimized value for the controller. Adjusting this to a higher value may impact performance. It is recommended to optimize the structure of the program first before resorting to modification of the watchdog time. |

Math Overflow

| Hardware Fault Type | Processor |

| Error Type | User Program Instructions |

| Error Code | Major Halt S1:1/3 set to 1; Math Overflow Trap S:5/0 set to 1; Major Error S:6 shows error code 20h |

| Error Description | A minor error bit is set at the end of the scan. Refer to S:5 minor error bits. |

| Cause | Division by Zero; Register unable to hold data; Data out of range |

| Resolution | (a) Program Download and Run (b) Automatic loading of program (c) Reset Overflow Trap bit S:5/0 (d) For instructions such as Add and Multiply, Reassign a register with appropriate length such as a double integer or a float. |

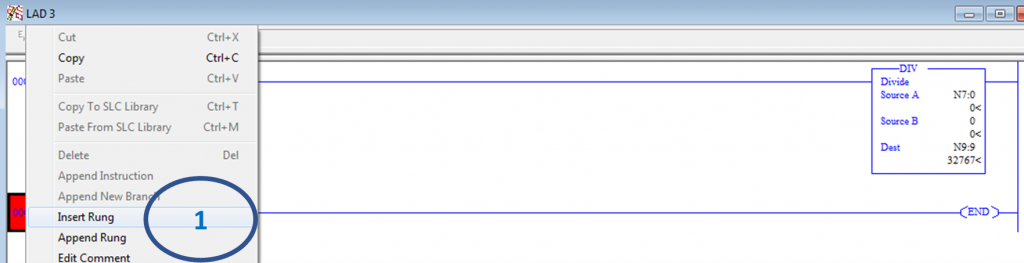

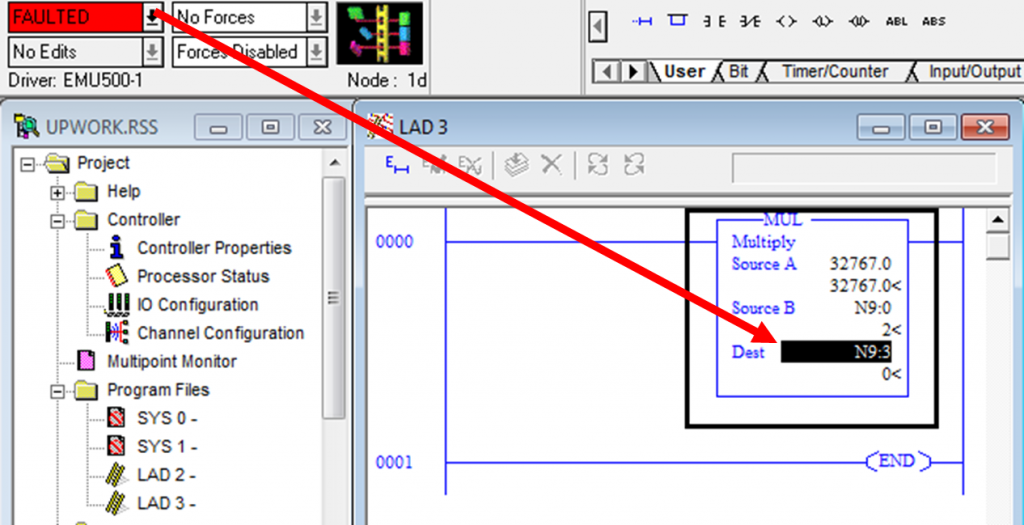

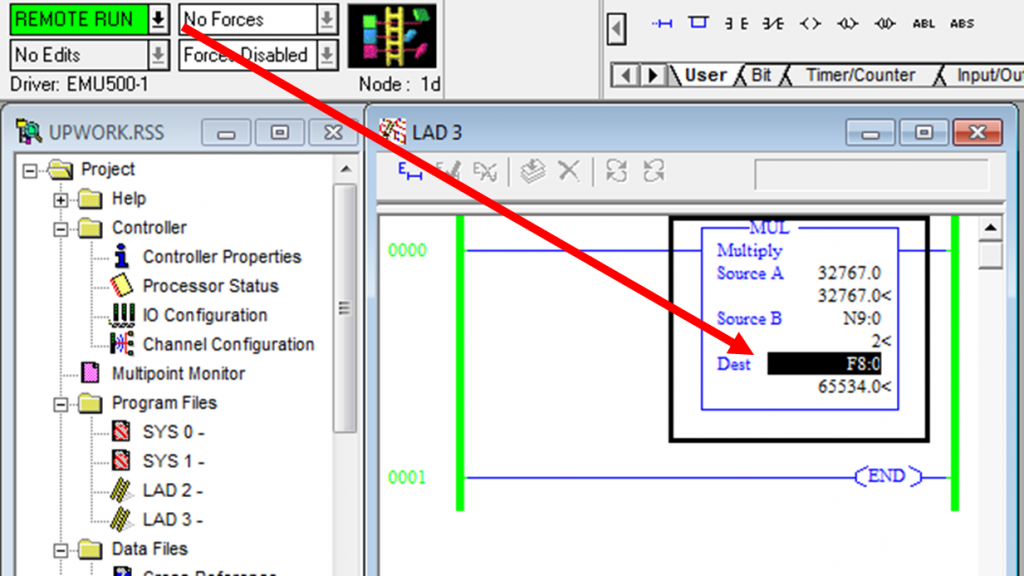

| Detailed Steps | Insert the OTU instruction to the new rung. Assign the OTU address to S:5/0.(a) To download program and Run, refer to the appendix (b) see detailed steps of NVRAM Error, to configure automatic program loading To reset Overflow trap bit; At the end of the faulted Mathematical operation, an overflow trap bit can be set to prevent the CPU from entering Faulted state. Unlatch Overflow trap bit S:5/0. It is recommended to perform an online edit to correct when applying resolution Insert rung after the faulted instruction or before the end of the program file. Insert the OTU instruction to the new rung. Assign the OTU address to S:5/0. Verify and accept rung edits. To re-assign a new register with appropriate length; In this simulation, as integer value ranges from +32768 to – 32767, multiplying 32767 by 2 results to 65,534 which triggers overflow as N9:3 has insufficient range, being an Integer. To correct this, the most common solution is use a Double integer or a Float data type to obtain sufficient range and prevent overflow. |

Memory Module Error

| Hardware Fault Type | Processor |

| Error Type | Powerup |

| Error Code | 0003/0007 |

| Error Description | Memory module memory error. This error can also occur when going to the REM Run mode / Failure during memory module transfer |

| Cause | Memory module is corrupted. |

| Resolution | (a) Reprogram the memory module (b) Replace memory module |

| Detailed Steps | (a) To download program and Run, refer to the appendix To replace memory module (a). Turn off the controller power or the entire SLC 500 rack. (b). Locate the memory module. |

(c). With the memory module located, user may now proceed with the replacement of the memory module.

For a modular controller, the memory module is removed by pressing the retainer clips at the top and bottom and carefully sliding out the module.

For a fixed hardware style controller, remove the compartment and locate the memory socket.

(d). Install the memory module. For a modular controller, Place the memory module onto the socket or connector and apply firm and gentle pressure to lock the module into place.

For a fixed hardware style controller, align the module over the socket and push gently into place. The memory module is equipped with hardware keying to avoid improper orientation.

(e). With the memory module installed, proceed with the re-installation of the hardware and applying power to the controller.

(f). Download user program and set controller mode to RUN.

Negative value for Timer and High-Speed Counter (HSC) preset

| Hardware Fault Type | Processor |

| Error Type | Program Instruction Error |

| Error Code | 0034 |

| Error Description | Negative accumulator or preset timer value was detected. Fixed processors with 24 VDC input only: A negative or zero HSC preset was detected. |

| Cause | The accumulated or preset value of a timer in the user program was detected as being negative. |

| Resolution | Program correction. If an arithmetic operation is configured to send preset value to a timer or a High-Speed Counter (HSC), ensure that the sum, difference, product or quotient does not result in negative or Zero (0) value. Similarly, if Data manipulation or conversion instructions are used for the same purpose, ensure that these manipulation and conversion does not result to Zero (0) or negative values as well. |

In the next section we will discuss SLC 500 I/O Faults.

Tags: SLC 500, SLC 500 Fault Troubleshooting, SLC 500 Faults, SLC 500 Troubleshooting

This entry was posted on April 2nd, 2021 and is filed under Allen-Bradley, Automation, Troubleshooting, Uncategorized. Both comments and pings are currently closed.

PDF Supply sells used surplus products. PDF Supply is not an authorized distributor, affiliate, or representative for the brands we carry. Products sold by PDF Supply come with PDF Supply’s 1-year, 2-year, or 3-year warranty and do not come with the original manufacturer’s warranty. Designated trademarks, brand names and brands appearing herein are the property of their respective owners. This website is not sanctioned or approved by any manufacturer or tradename listed.

Rockwell Disclaimer: The product is used surplus. PDF Supply is not an authorized surplus dealer or affiliate for the Manufacturer of this product. The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because PDF Supply is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply. While many Allen-Bradley PLC products will have firmware already installed, PDF Supply makes no representation as to whether a PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. PDF Supply also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from Rockwell, its distributors, or any other source. PDF Supply also makes no representations as to your right to install any such firmware on the product. PDF Supply will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.