GE / IP FANUC Series 90/30 In Stock

Examples of PLC Inputs and Outputs

PLC Inputs and Outputs Overview

A Programmable Logic Controller (PLC) is a microprocessor-based digital electronic device, which uses a programmable non-volatile memory to store user-defined instructions and implement specific control functions like programming logic, and sequencing, timing, counting, and arithmetic operations to control various electro-mechanical systems and industrial processes. As a user, you can program a PLC using a programming device like a Hand-Held Monitor (HHM) or a personal computer connected to the PLC through a LAN cable. Today, PLCs are considered the backbone of industrial automation globally.

Like any other electronic device, a PLC controller needs to be provided with input so as to yield output. For example, you can press a Push Button on the PLC control panel to start a Motor. In this case, the Pushbutton is the PLC input device while the Motor is the output device. However, the working principle of a PLC system is not as simple as such. Because to control a process or machinery, the PLC system must be equipped with sophisticated electronic Input and Output (I/O) modules. These I/O modules interface the PLC CPU to the real world, or rather to the field input/output devices.

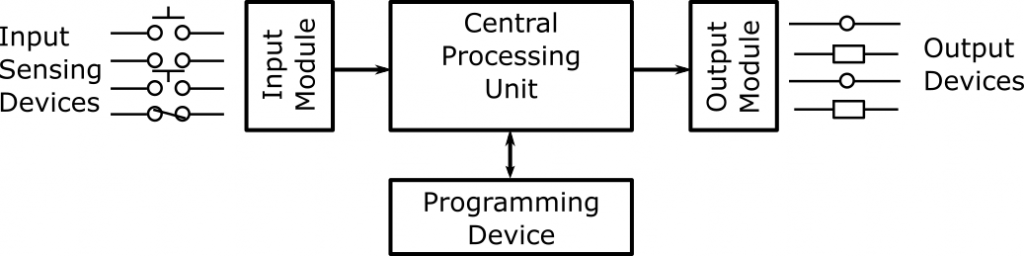

The Input modules gather data from all field input devices and transmit it to the PLC processor (CPU) as voltage or current signals. The received signals are the PLC inputs. The CPU then processes the received information as pre-programmed data, which it uses together with the execution results of its programmed logic to control the field output devices via the Output modules. Thus, PLC outputs are the appropriate control commands that the PLC CPU sends out to control/operate physical devices upon executing the user program from its Random-Access Memory (RAM). The block diagram below illustrates the principle of operation of a PLC system:

Digital PLC Inputs

Digital inputs are the most common types of inputs in PLC systems; due to the fact that PLCs are digital electronic devices themselves, thus, they’re able to easily process digital signals. A digital PLC input is basically a binary signal that is either ON or OFF, and which is applied to the PLC processor from a digital field input device. The concept of digital signals is based on the binary number system, which consists of only two possible digits, 1 or 0. Where 1 represents a HIGH state and 0 indicates a LOW state. However, in most PLCs, the HIGH signals are not represented by 1Volt but by 24Volts dc, because PLCs normally operate on 24V DC. In such a case, the PLC will indicate HIGH at its input side if the output voltage of the interfaced field input device is 24V DC.

Digital Input modules in PLC systems use the digital inputs to determine the status (i.e. ON or OFF) of specific field input devices. For example, if a certain PLC input module has an operating voltage of 24Volts DC and it receives a 0V DC input signal then it’ll identify the status of the connected field device as OFF. Whereas, a 24V DC input signal to that PLC input module will indicate an ON status of the field device. These digital PLC input modules usually identify the status of field input devices in different ways including:

- General Status: TRUE/FALSE, HIGH/LOW, and 1/0

- Load Condition: ON/OFF

- Switching Mechanism: ENERGIZED/DE-ENERGIZED, ACTIVATED/DEACTIVATED

- Switching Contact Status: CLOSED/OPEN

Examples of Digital Field Input Devices in PLCs

Digital field input devices provide digital input signals to the PLC system via the digital input modules. Some of the most common digital field input devices that you’re likely to come across in almost all PLC applications include:

A) START/STOP Push Buttons

Start/Stop Pushbuttons are usually located in a PLC control panel. They function either by making or breaking contact. They are thus classified as either Normally Closed (NC) or Normally Open (NO). When a NO push button is connected to a digital input module it creates an OPEN logic circuit with no electrical continuity, hence, current cannot flow through.

On the other hand, when you connect a Normally Closed (NC) push button to a digital PLC input module it creates a CLOSED logic circuit with electrical continuity. This allows current to flow through the created logic circuit.

B) Proximity Sensors

Proximity sensors in PLCs are used to detect the presence or absence of various nearby target objects without making contact. Instead, they determine changes in the return signal of a beam of emitted electromagnetic radiation (like infrared light) or electromagnetic field to detect the presence or absence of the targets. Different target objects with varying material properties require different types of proximity sensors. For example, detection of metal targets in industrial fabrication processes requires the use of inductive proximity sensors. For plastic targets consider using capacitive proximity sensors.

Like switches, proximity sensors provide binary outputs and that’s why they’re sometimes referred to as proximity switches. For instance, the state of a photoelectric sensor (a common proximity sensor) will change from LOW to HIGH when emitted Infrared light hits the sensor’s receiver. Such a sensor uses a Light Emitting Diode (LED) as the Infrared emitter and photodiodes/ phototransistors as receivers.

Similarly, PNP and NPN proximity sensors are also good examples of digital field input devices which provide HIGH or LOW voltage input signals to a PLC system. For instance, a PNP sensor will give a HIGH voltage signal on detecting an object and a LOW voltage signal when no target is detected. On the other hand, NPN sensors give a LOW voltage output on detecting an object because they are naturally ‘ON’. But they’ll give a HIGH voltage signal when the target object is removed from their detection range.

C) Limit Switches

Limit switches change their state whenever a specified or pre-determined limit is attained. They are used in PLC-controlled systems to specify process stops. There are a variety of available limit switches for use with PLCs, this allows users the flexibility to choose the physical quantities they wish to limit. The available limit switches include:

- Temperature Limit Switches or Thermostats: These switches monitor temperature changes in a PLC-controlled system by indicating when minimum or maximum system temperatures are attained. Thermostats can either be Normally Closed (NC) or Normally Open (NO) depending on the type of industrial application.

- Pressure Limit Switches: They change their state whenever the liquid or gas in a container attains a specified high enough pressure. For this reason, they are mainly used in liquid or gas containers where pressure regulation is crucial. Pressure limit switches are either Normally Open (NO) or Normally Closed (NC).

- Level Limit Switches: Level switches also known as Level Sensors, are used to regulate the height of liquid within a container, usually a tank. They are mainly utilized in PLC systems controlling liquid levels in conjunction with inlet and outlet valves.

Analog PLC Inputs

Analog PLC inputs are continuous signals from field input devices to the PLC CPU via the analog input modules. They are characterized by voltage or current signals whose range of values is much more than just 1 or 0. For example, analog input signals received by a PLC can either be 12-bit or 13-bit signals. Thus, an analog PLC input exists when variable current or voltage values received from a field input sensor correspond to a floating decimal.

In general, analog input modules in PLC control systems measure current and voltage signals from field input devices in the standard ranges of 0-20 mA(milliamperes), 4-20 mA, 1-5 VDC (volts DC), 0-10 VDC, etc., respectively. So, a connected analog field input device will provide voltage or current signals to the analog input module with any intermittent value within the specified extreme limits.

Note: Voltage and current signals are the most commonly used types of analog PLC input signals, but you can still apply other types of analog signals to the PLC as inputs. Voltage-mode analog inputs in PLCs are extensively used in pressure sensing, temperature sensing, luminance sensing, and distance sensing. While current-mode analog PLC inputs are normally used in applications requiring long-distance signal transmission.

Examples of Analog Field Input Devices in PLCs

A) Thermocouple Sensors

A thermocouple is a type of sensor used to detect temperature variations. It consists of two dissimilar metal wires (called thermos wires), which are joined at one end to form a hot junction from where the temperature is measured. While the free ends of the two dissimilar wires form the cold junction, which provides the reference temperature for the thermocouple measurements at the hot junction.

Heating or cooling of the hot junction creates a thermoelectric voltage that correlates to the temperature measurements of the thermocouple. The generated thermoelectric voltage signals are usually small analog signals that can only be measured in the millivolt (mV) range. Thus, if properly configured, a thermocouple can provide temperature measurements over a wide range of values.

Due to their versatility as temperature sensors, thermocouples are commonly used in a wide range of applications from utilities and regular appliances to industrial usage. The thermocouple sensors used as field input devices in PLC control systems are robust devices characterized by improved linearity and accuracy as well as faster response times. They also include thermos wires of specially developed metal alloys, which enhances their capability to measure wider temperature ranges. For example, you’ll find that some thermocouples used in PLCs can measure very high operating temperatures of up to 2912℉(1600℃−white heat) for special industrial applications.

B) Resistance Temperature Detectors (RTDs)

RTDs are passive temperature sensing devices whose resistance values change as per temperature variations. They require external current for excitation and they don’t produce their own outputs. They are thus used with external electronic devices that can measure the RTD resistance by allowing a small amount of electric current to pass through the RTD’s resistive element.

The electric current flowing through the resistive element of the RTD generates a resistance value, which is measured by the external electronic device. The measuring device then correlates the obtained resistance values to its temperature, according to the resistance characteristics of the RTD’s resistive element in use.

RTDs are popular temperature detectors as they exhibit the most linear relation between temperature variations of an external device and their resistance signal. That means, that if the temperature of the electronic device is increased, the resistance of the RTD sensor will also increase accordingly. They are also more stable, more robust, and highly accurate compared to thermocouple sensors.

Note: RTDs are prone to self-heating since they require excitation current from external electronic devices. Thus, the amount of excitation current applied to RTD resistive elements is limited to <1 mA to 5 mA (milliamperes), so as to avoid the risk of self-heating.

C) Displacement Sensors

Displacement sensors are also referred to as Position sensors. They measure the distance between a specific reference point and the location of a target object. So, they are undoubtedly analog field input devices that provide a range of displacement values to analog PLC input modules. They are often used in industrial fabrication processes requiring higher levels of precision.

Common displacement sensors include:

- Rotary and Linear Potentiometers: These two potentiometers use Ohm’s Law principle to indicate changes in the displacement of target objects. In that regard, any changes in their output voltage represent distance variations of the target object. Rotary potentiometers in PLC systems measure angular distance, so they are used when the target objects exhibit rotational (circular) motion. Whereas, linear potentiometers are used to measure the distance of objects being displaced along a straight line.

- Linear Variable Differential Transformer: An LVDT is a type of electromechanical transducer or rather an electrical transformer that is used to measure the linear displacement of a target object. It achieves this by converting the rectilinear motion of a mechanically coupled target object into a corresponding electrical signal. LVTDs are used in PLC-controlled systems requiring constant AC voltage to represent changes in the distance along a straight line.

Digital PLC Outputs

Digital PLC outputs are control circuits that use only binary data (1 and 0) to give the PLC CPU control over field output devices. A digital PLC output is thus a processed binary control output from the PLC to the field devices. Digital PLC outputs are typically used to provide an ON or OFF (OPEN or CLOSED) control scheme to any device or system being controlled by the connected PLC.

Types of Digital PLC Outputs

Digital PLC outputs are classified into three categories namely:

- Relay PLC Outputs: The relay outputs from PLCs are used to operate both DC (Direct Current) and AC (Alternating Current) field output devices. They provide low resistance control of up to 2A (Amperes).

- Transistor PLC Outputs: Transistor outputs are voltage-dependent and they can only operate DC loads. PLC control systems providing transistor outputs are mainly used in low-power DC circuitry such as within microprocessors and in applications that require faster switching operations like controlling lights.

- TRIAC PLC Outputs: TRIAC is a term that means Triode for Alternating Current (AC). TRIACs are silicon-based, solid-state electronic switches that are activated by a small amount of control voltage from a PLC for example. Their working principle is similar to that of MOSFET (Metal Oxide Semiconductor Field Effect Transistor) transistors. TRIAC PLC outputs are ideal for controlling low-power AC loads such as motor starters, lighting systems, and contactors.

Examples of Digital Field Output Devices in PLCs

Digital PLC outputs can be used to control the following field output devices:

A) Indicator Lights

The simplest example of a digital output device that can be controlled by a PLC is the light bulb. As a digital output from the PLC can turn ON the light bulb or turn it OFF. Similarly, indicators such as Green/Red pilot lights are controlled by PLCs using the same principle as the light bulb control. For example, a digital PLC output can turn ON the Red pilot light to indicate that the machine/system being controlled is not functioning.

B) Alarms

Alarms in PLC-controlled systems provide notifications of higher urgency. For example, a horn, a blinking red light, or a buzzer could indicate the occurrence of a hazardous condition in the PLC controlled system. Buzzers are creatively utilized in PLC control systems by varying their ON duration or ON/OFF intervals. A buzzer is simply an electronic device that produces a single frequency sound when powered by a voltage source. They are more appropriate for use as alarms compared to indicators, because nobody wants a buzzer sounding 24hrs a day.

C) Actuators

These are devices that convert an electrical or control signal into linear or rotary mechanical motion. Simply put, an actuator translates the digital output signal from a PLC into practical movement operations. Actuators are usually connected to high-power AC or DC voltage sources, but they do have coils that allow small DC voltage to control their switching.

D) Solenoid Valves

A solenoid valve is simply an electromechanical valve that is electrically controlled. The two most common types of solenoid valves are Direct Acting and Pilot Operated. Usually, these valves are used to control the flow directions of fluids in hydraulic and pneumatic systems. A typical solenoid valve includes a solenoid, which is an electrical coil having a movable ferromagnetic plunger (core) in its center.

In its resting position, the plunger normally closes off an orifice. If DC control voltage is applied to the solenoid from a PLC, it closes the solenoid switch–that connects the solenoid to another power source–allowing electric current to pass through the coil. This creates a strong magnetic field that pulls the plunger upwards into the valve’s frame, thereby opening the orifice. When the DC control voltage is removed from the solenoid circuit, the plunger resumes its original position by use of spring force. This is the basic principle used to OPEN and CLOSE PLC controlled solenoid valves.

Examples of Analog PLC Outputs

An analog PLC output is a time-varying or continuous signal from the PLC CPU to the field output devices. Basically, PLCs provide two types of analog output signals-current and voltage. Hence, an analog PLC output can either be a current or voltage signal. In most PLC systems, the analog output modules supply either voltage or current signals to field output devices in standard ranges of ±5 V(Volts), ±10 V, 0…5V, 0…10 V, 0…20 mA(milliamperes), or 4…20 mA, respectively.

Analog PLC outputs are mainly used to control or operate field devices in industrial environments. For example, you can provide a speed reference signal to a Variable Frequency Drive (VFD) using an analog PLC output. Also, in case you’re using a PLC control system to measure the pressure of a piping system, you can readily use an analog pressure meter as a field output device to display the pressure readings.

In addition, the implementation of analog PLC outputs can also be seen in the operation of water level meters, temperature gauges, and control of various other equipment/machinery. For instance, a 4…20 mA analog PLC output can be used to operate a temperature gauge from −20℉ (−28.89℃) to 200℉ (−93.33℃). Similarly, a 0…5V DC analog PLC output can be used to control the power output of an electric generator from let’s say 0…2000kW (Kilo-Watts). As you can see, there are many field devices that make use of analog PLC outputs.

This entry was posted on May 23rd, 2022 and is filed under PLC, Uncategorized. Both comments and pings are currently closed.

PDF Supply sells used surplus products. PDF Supply is not an authorized distributor, affiliate, or representative for the brands we carry. Products sold by PDF Supply come with PDF Supply’s 1-year, 2-year, or 3-year warranty and do not come with the original manufacturer’s warranty. Designated trademarks, brand names and brands appearing herein are the property of their respective owners. This website is not sanctioned or approved by any manufacturer or tradename listed.

Rockwell Disclaimer: The product is used surplus. PDF Supply is not an authorized surplus dealer or affiliate for the Manufacturer of this product. The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because PDF Supply is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply. While many Allen-Bradley PLC products will have firmware already installed, PDF Supply makes no representation as to whether a PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. PDF Supply also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from Rockwell, its distributors, or any other source. PDF Supply also makes no representations as to your right to install any such firmware on the product. PDF Supply will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.